DTF Transfer Printers revolutionize custom printing by offering swift, efficient production of high-quality, versatile designs on light fabrics. This technology streamlines workflows, enhances print quality, and empowers businesses from small startups to designers, while requiring initial investment, skill, and maintenance.

“Unleash efficiency in your printing processes with DTF (Direct-to-Film) transfer printers. This article explores how these innovative devices can revolutionize workflows, offering faster turnaround times and enhanced quality. We’ll guide you through the implementation process, from understanding the technology to reaping benefits like streamlined production and reduced waste. Despite potential challenges, adopting DTF transfer printing can be a game-changer for businesses seeking advanced, automated solutions.”

- Understanding DTF Transfer Printers and Their Potential

- Automating Workflows: Steps to Implement DTF Technology

- Benefits and Challenges of Adopting DTF Transfer Printing

Understanding DTF Transfer Printers and Their Potential

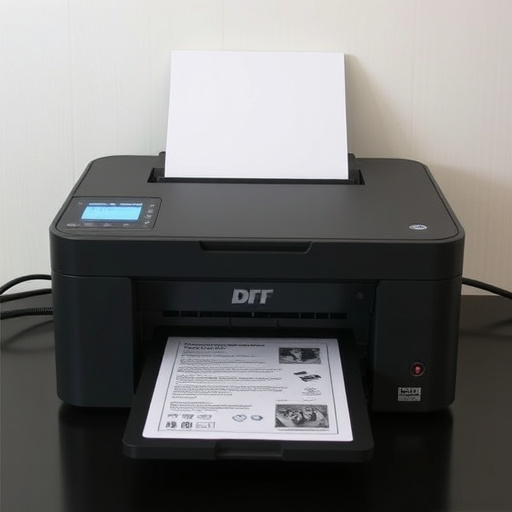

DTF Transfer Printers are revolutionizing the way businesses approach custom printing and design. These direct to film (DTF) printers offer a streamlined, efficient method for creating high-quality prints on various materials, particularly light fabrics. By eliminating the need for complex setup processes, DTF technology simplifies the printing process.

The potential of DTF Transfer Printers lies in their versatility and speed. They can produce detailed, vibrant designs with remarkable precision, making them ideal for small-batch production or one-off projects. The use of DTF heat transfer paper ensures consistent results, enabling businesses to effortlessly transition from digital design to physical product, a process that was once time-consuming and prone to errors. This technology is transforming industries, allowing entrepreneurs and designers to bring their creative visions to life with ease and speed.

Automating Workflows: Steps to Implement DTF Technology

Implementing DTF (Direct to Fabric) technology for your printing needs can significantly streamline and automate workflows, especially in custom t shirt production or bulk dft shirt production. Here’s a step-by-step guide on how to make the transition:

1. Assess Your Requirements: Begin by evaluating your current printing processes and identifying areas where DTF Transfer Printers can offer improvements. Consider factors like print quality, speed, material compatibility, and ease of use. DTF transfer sheets provide a versatile solution for various fabrics, allowing you to print on custom designs with exceptional detail and vibrancy.

2. Choose the Right Equipment: Select a high-quality DTF Transfer Printer that aligns with your production capacity and desired output. These printers are designed to efficiently produce complex designs directly onto fabric, eliminating the need for intermediate steps. Ensure the model you choose supports the material types and print resolutions required for your custom t shirt ventures or bulk production runs.

Benefits and Challenges of Adopting DTF Transfer Printing

Adopting DTF (Direct-to-Fabric) Transfer Printing offers businesses numerous benefits, especially in the apparel and textile industry. This technology allows for precise, high-quality printing directly onto various fabrics, enabling small and medium-sized enterprises to produce custom designs with ease. With a DTF transfer printer, brands can achieve vibrant colors, intricate details, and soft handfeel on both light and dark fabrics using eco-friendly methods. It streamlines production processes, reduces set-up times, and minimizes waste, making it an attractive option for those seeking efficient and cost-effective printing solutions.

However, the path to implementing DTF transfer printing isn’t without challenges. Initial investment costs can be high, requiring a significant financial commitment. Additionally, mastering the technology requires skill and experience in fabric preparation, printer calibration, and ink application to prevent issues like bleeding, smudging, or uneven prints. Furthermore, ensuring compatibility with different fabric types and maintaining print quality over time demands ongoing care and maintenance of the equipment. Despite these challenges, many businesses find that the benefits of DTF printing for dark fabrics outweigh the difficulties, making it a game-changer in modern textile production when utilized effectively.

DTF transfer printers offer a game-changing solution for streamlining workflows in various industries. By automating the print process, these innovative machines enhance productivity, reduce manual errors, and enable faster turnaround times. While initial adoption may present challenges, the benefits of DTF technology are undeniable. As you navigate the digital printing landscape, consider how DTF transfer printers can revolutionize your production processes and foster a more efficient, modern approach to manufacturing.