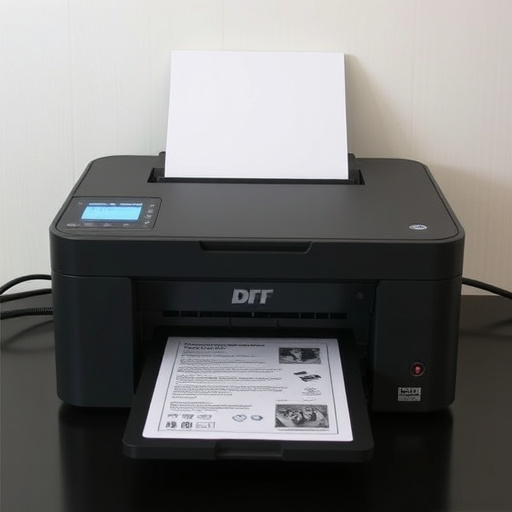

Regular cleaning and maintenance are key to extending the lifespan of a DTF Transfer Printer, ensuring optimal performance and productivity. This includes consistent post-use cleaning, scheduled deep cleanings every few weeks, proper care during custom order periods, routine print head and plate cleaning to prevent clogs, calibration for accurate color reproduction, adhering to manufacturer guidelines, power cycling, disassembling carefully, using compressed air and isopropyl alcohol (70% concentration) for deep cleaning, and thorough drying before reassembling. Proper maintenance leads to an efficient, cost-effective printing process.

“Maximize the lifespan of your DTF transfer printer with our comprehensive guide. Learn how regular maintenance and cleaning can prevent buildup and wear, ensuring smooth operation for years to come. Discover proper handling and storage techniques to avoid common pitfalls that shorten printer lifespans. Additionally, we explore the impact of print media and settings, guiding you in choosing compatible materials and consumables for optimal performance. Implement these strategies to extend the life of your DTF transfer printer.”

- Regular Maintenance and Cleaning

- – Importance of routine maintenance

- – Steps for cleaning the printer and its components

Regular Maintenance and Cleaning

Regular maintenance and cleaning are essential aspects of prolonging the lifespan of your DTF Transfer Printer. A well-maintained printer ensures optimal performance, enhances productivity, and prevents costly breakdowns. Start by creating a consistent cleaning routine to keep your machine in top condition. This includes regularly wiping down the print bed, removing any residual ink or debris after each use. Use recommended cleaning solutions suitable for DTF printers to avoid damaging the hardware.

Additionally, schedule deep cleaning sessions at interval points, such as every few weeks or after handling heavy custom orders (DTF transfers ready to press). This involves a thorough inspection of all components, including nozzles, heaters, and print heads. Cleaning or replacing worn-out parts promptly will prevent ink buildup, blockages, and potential printing issues. Remember, a well-cared-for DTF printer is key to fulfilling your dtf custom orders efficiently and consistently.

– Importance of routine maintenance

Regular maintenance is key to prolonging the life of your DTF Transfer Printer and ensuring it produces high-quality vibrant designs consistently. It’s akin to giving your printer a wellness check-up, addressing any potential issues before they become major problems. A simple yet effective routine involves keeping the printer clean, especially the print head and plates, which can clog or harden over time. Use recommended cleaning solutions and brushes to gently remove any buildup, ensuring optimal ink flow for crisp custom DTF transfers.

Additionally, consistent calibration ensures accurate color reproduction and precise registration of designs on the material. Most printers come with built-in calibration tools that guide you through the process. Following the manufacturer’s guidelines for maintenance, including regular updates and firmware checks, will also contribute to the overall health and longevity of your DTF gang sheet builder.

– Steps for cleaning the printer and its components

Regular cleaning is key to extending the lifespan of your DTF Transfer Printer and ensuring high-quality, durable prints. Begin by power cycling your printer—turn it off, unplug it, wait a few minutes, then plug it back in and turn it on again. This refreshes the system and prepares it for cleaning. Next, carefully disassemble the printer according to the manufacturer’s instructions. Pay close attention to the printhead, rollers, and any nozzles as these are particularly prone to clogging. Use a soft brush or compressed air cans to remove any dust or debris accumulated during printing.

For deep cleaning, use isopropyl alcohol (70% concentration) on a lint-free cloth to wipe down all surfaces, especially those in contact with the print medium. Always ensure that the printer components are completely dry before reassembling. Remember, a clean printer means vibrant, precise UV DTF transfers and a cost-effective, efficient printing process.

To ensure your DTF Transfer Printer’s longevity, regular maintenance and cleaning are key. By following simple steps to keep your printer in optimal condition, you can enjoy consistent, high-quality prints for years to come. Remember that proactive care is always more effective and efficient than reactive repairs, so make these practices a routine part of your printing journey.