DTF (Direct to Film) Transfer Printing offers high-quality, custom designs on fabric, plastic, and wood using a specialized printer that blends traditional and modern techniques. To achieve best results, designers should prepare files with 300 DPI vector graphics for crispness, tailor print settings to specific substrates like t-shirts, and maintain printers by cleaning print heads, calibrating colors, checking ink levels, and optimizing settings based on fabric types to ensure consistently excellent prints.

“Unlock the secrets of achieving crisp, high-quality prints with DTF (Direct to Film) printers. This comprehensive guide offers invaluable insights into the unique transfer printing process. Learn how to prepare your designs for optimal results, ensuring every detail is conveyed accurately. Discover essential maintenance and troubleshooting tips to maintain consistent print quality over time. Optimize your DTF Transfer Printer’s potential and elevate your printing game today.”

- Understanding DTF Transfer Printing Process

- Preparing Your Designs for Optimal Results

- Maintenance and Troubleshooting Tips for Consistent Quality

Understanding DTF Transfer Printing Process

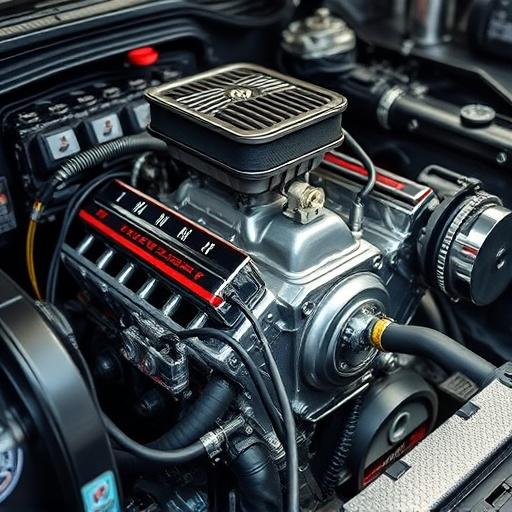

The DTF (Direct to Film) Transfer Printing process involves a precise and intricate series of steps to achieve crisp, high-quality prints. This method utilizes a DTF transfer printer that combines elements of traditional printing techniques with modern technology. The process begins with preparing the design or artwork, which can be done using specialized software designed for DTF transfers. Once the design is finalized, it’s printed onto transparent dtf transfer sheets using either solvent or UV inks, depending on the printer and desired outcome.

These transfer sheets act as a temporary carrier for the image, allowing for precise alignment during the transfer process. The sheet is then carefully applied to the substrate—whether it’s fabric, plastic, or wood—and heat is used to fuse the ink onto the material. This direct application ensures that every detail of the design is accurately replicated, resulting in crisp lines and vibrant colors. Custom DTF transfers offer a unique advantage, enabling businesses and artists to create personalized designs with intricate details, making it an appealing choice for various applications, from fashion and textiles to signage and decorative items.

Preparing Your Designs for Optimal Results

To achieve the best results with a DTF Transfer Printer, it’s crucial to prepare your design files meticulously. Start by ensuring your artwork is in high resolution, typically 300 DPI or higher, as this guarantees sharp and detailed prints. Use vector graphics whenever possible, as they offer unmatched precision and scalability without pixelation.

Additionally, consider the printing surface when designing. For DTF printing on t-shirts and similar garments, create custom sheets for heat pressing designs onto the fabric. This involves careful color management to avoid discoloration or fading during the transfer process. Ensure your design elements are properly aligned and positioned, as any misalignment can lead to unsatisfactory prints.

Maintenance and Troubleshooting Tips for Consistent Quality

Regular maintenance is key to ensuring your DTF transfer printer produces consistently crisp prints. Start by cleaning the print head after every use to prevent buildup and clogging, which can lead to poor quality outputs. Use recommended cleaning solutions suitable for your specific DTF printer model. Additionally, calibrate the printer regularly to ensure precise color reproduction and optimal image placement on the substrate.

Troubleshooting common issues can help maintain consistent quality. If you encounter light or inconsistent prints, double-check the ink levels and ensure they are adequate. Verify that the custom sheets for heat pressing designs onto garments are properly aligned and positioned in the printer. For best results with lighter fabrics, optimize your DTF printing settings and consider adjusting the pressure and temperature to avoid bleeding or smudging.

Getting crisp prints with a DTF Transfer Printer requires understanding the process, preparing your designs optimally, and maintaining the printer consistently. By following these tips, you can ensure high-quality, detailed prints that bring your designs to life. Remember, optimal results come from a well-maintained machine and carefully prepared artwork, making regular upkeep and careful design preparation key components of successful DTF Transfer Printing.